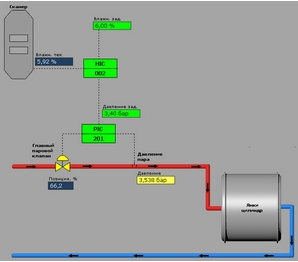

As an addition to the quality control system (O-frame or C-frame) is a moisture control loop in the longitudinal direction. The control object of this circuit is (depending on the steam-condensate system) either the main steam valve, or steam for the first drying group, or steam in the final drying group with stabilization of the main steam. The principle of operation of the system is based on measuring the current humidity with a sensor and controlling a steam valve.

regulation scheme

The main operating modes of the system:

– local (local control panel);

– remote (APCS system).

In remote mode, the system is controlled by:

– manual mode;

– automatic;

– cascade.

The processing of the “break”, “little steam” modes, emergency situations is also realized. In this case, the system will include the following functions:

– by the value of humidity from the humidity sensor, keep the vapor pressure at the minimum required level;

– to heat the drying cylinder according to the established algorithm (smooth increase in steam pressure over time at the initial start of the machine)

– cover the steam to a sufficient value in case of breaks, temporary shutdowns, and the like. (Covering steam in case of breaks is carried out both in automatic mode (breakage sensor) and by the PM operator)

– control the temperature of the incoming steam;

– control all parameters of the system, keeping trends, logs, etc.

This system is an intermediate link between the quality control system and the already installed teaching staff management system.